Our one year delay will, thankfully, be only a one year delay. My partner and I are nearly ready to go, and even have a fairly solid date for untying the lines: April 24th. As I write this, we’re living out of a hotel while the boat is hauled out to deal with some under-the-waterline modifications we need to make. Hopefully we’ll be back in the water in about two weeks, and then we’ll have about a month to finish our prep.

But first, let’s back up a little bit and take a look at what we’ve gotten done in the last eight months since I last posted. Not just boat work either; I finished a few knives and am finishing up a few more in the last few weeks until I close my workshop up.

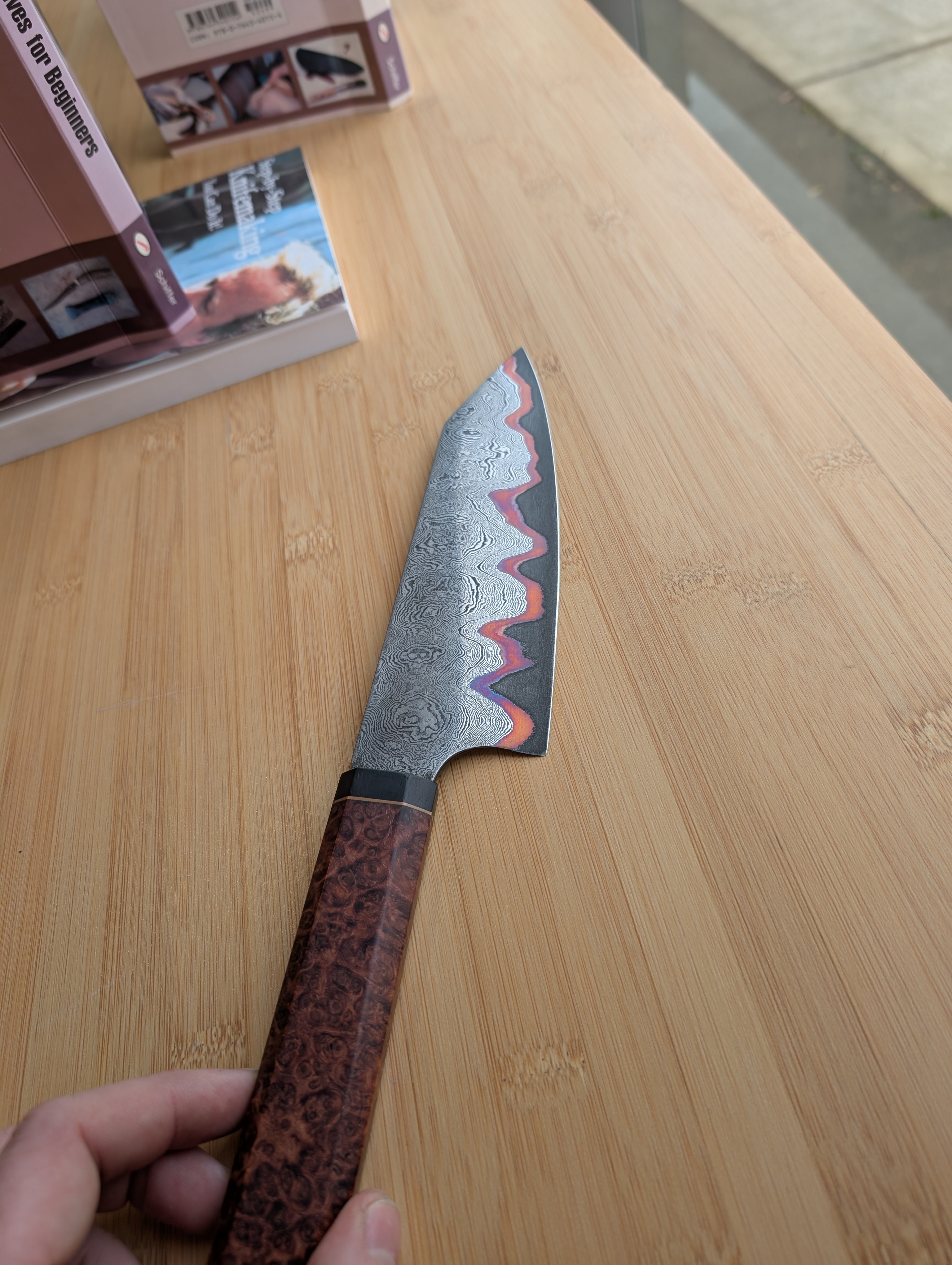

Knives

My knifemaking pace has been pretty slow the last bunch of months, but I did complete several AEB-L stainless chef knives as well as the lovely blade I posted a preview of at the end of the previous post. That knife is now on sale at Seattle Edge Sharpening (link to come once a page is posted for it).

They’ve also got a matched set of knives I made still up for sale as well, which you can find here. In the second picture you can see the beautiful natural patina that is forming over time on the brass & copper.

Boat Updates Completed

I barely know where to begin, so I suppose we’ll start with a bulleted list and expand out from there.

- Bought an ePropulsion Spirit 1.0 for the dinghy and sold the Tohatsu 6hp

- Installed a blower fan pointing at the high-output alternator to help keep it cool (mostly a success)

- Upgraded from our existing 150′ chain + 200′ rope to 250′ chain + 100′ rope so we can handle deeper anchorages better

- Got a new genoa made from Hydra Net from Ballard Sails to match our mains’l

- Had all our interior cushions restuffed with new foam

- Had an entirely new set of cockpit cushions custom made

- Had the solar shade made with the two 170W flexible panels

- Replaced the wiring for the VHF->cockpit mic (an Icom CommandMic II) so our boat’s main VHF can be used from the helm

Electric Outboard

In some ways this might look like a slightly odd decision: why downgrade in power from an engine able to get the dinghy up on plane to an electric motor that tops out just below that speed?

Two factors:

- Getting a flammable fuel off the boat. I no longer need to carry gasoline.

- Getting an outboard that is light-weight enough for my partner to be able to handle putting on and removing it from the dinghy herself.

The Tohatsu 6hp was a great engine, but it was heavy enough that my partner would never be able to carry it herself, and I struggled with it (you try carrying a heavy awkward object from the back of your boat onto a dinghy. It’s really difficult!)

Given our solar results last summer and the addition of the solar shade, keeping the outboard battery topped off won’t be a problem, and having a near-silent method of propulsion for the dinghy is much better for wildlife viewing! So, while giving up the speed of the 6hp is a bit of a sacrifice, I think it will be worth it.

New genoa

Strictly speaking, we didn’t need a new genoa. But the original one was getting older, and since we had the time and I had the money, I decided to go for it. It’s the same size as the old one (it’s a ~130% size for the sailors out there), but like our mains’l, it’s made from Hydra Net, so it’s got a useful lifespan of 10-15 years, double that of Dacron. In early April, Ballard Sails will also install a track + pole on our mast which will help with downwind sailing.

We’re sticking with a pretty simple sail plan since there are only two of us sailing the boat and I didn’t want to have to make the major rigging additions to add an inner forestay:

- In-mast furling main (Hydra Net, Ballard Sails)

- Furling 130% genoa (Hydra Net, Ballard Sails)

- Storm trys’l (Dacron, Ballard Sails)

- Gale Sail (Dacron, ATN)

That’s right: no spinnaker or Code 0 or other big downwind sail. We’re going to make do with our simple sail inventory and I think we’re going to be just fine. Can we sail fully optimally all the time? Nope. But we can sail just fine in nearly any conditions and at any point of sail.

New cockpit cushions

Ever since I bought Kestrel I’d wanted to replace the cockpit cushions, but figured I might have to wait until we got to Mexico. The originals were vinyl and the interior foam was mostly useless. But, late last summer, someone in our marina posted on the corkboard outside the laundry room that he had a canvas business.

I don’t have any good pictures at the moment due to how big of a mess the cockpit has been, but I’ll take some soon.

So now we’ve got new cushions in the cockpit! Instead of vinyl (which in the heat of the tropics would get sticky on bare skin!) we got Sunbrella canvas just like our enclosure is made from which should stay comfortable no matter the weather or our attire.

Solar shade

After the cockpit cushions were done, the same person built the solar shade I’d designed. I don’t have a picture of it set up at the moment (due mostly to the time of year, there’s no need for it!), but will certainly post pictures of us at anchor in the future with the solar shade up. I also still need to finish installing my solution for plugging/unplugging the panels from the MPPT, which involves an XT60 connector (usually used for FPV drone battery chargers).

Boat projects in progress

Like I said at the top, Kestrel is currently hauled out of the water. Here’s what being done at the yard:

- Replace engine raw water intake seacock (I noticed a small leak when I turn the handle)

- Install underwater swim lights under transom (2x1800L Apelo A1 blue/white) (below waterline)

- Install raw water intake + seacock for watermaker (below waterline)

- Install bring discharge + seacock for watermaker (above waterline)

- Install keel cooler for freezer

- Drill 1.5″ diameter hole between freezer compartment and the spot the freezer compressor will be installed

As you might be able to tell, this is a lot of prep work for a few projects that I’ll be finishing. I don’t need the yard to do any of the hookups, electrical or otherwise, I just need things installed so I can finish these projects.

Watermaker

While my initial plans for the through-hulls with the watermaker (a Schenker Zen 50) turned out to be a bit optimistic, it oddly has been turning out to be the easier of the two projects (between it and the freezer), which is a bit surprising. With the new raw water intake and brine discharge seacocks installed, I will be able to move on to physically installing the components and hooking things up. There will be a full blog entry on the watermaker installation coming up in late March/early April once I’ve completed it.

Freezer project

Similarly, I need the keel cooler physically installed and the 1.5″ hole drilled before I can proceed on the installation. You might wonder why I haven’t drilled the hole myself! Unfortunately, it’s a rather difficult thing to measure the angles on correctly without a jig. The yard is much more practiced at this sort of thing and will be able to get it right on the first try.

From there, I’ll install the compressor and the cold plates. The primary thing I’m worried about here is the copper tubing; the installation kit has significantly more of it than I need and the solution for having too much appears to simply be “curl it up in tight loops”. I can’t very well cut it since the entire system is pre-charged, though if it does come to that I will likely need to hire an HVAC technician.

The freezer install will also be getting its own blog entry in late March/early April.

Swim lights

These are more of a fun thing, but since we were getting hauled out I figured it was worth getting done. The yard will be installing a pair of Apelo A1 blue/white lights under the swim step, and I’ll be doing the wiring myself.

I’m really looking forward to using these, both in the cold waters up in this area as well in places where it’s warm enough to swim. Watching little fish in the water late at night is a lot of fun, and in crowded anchorages we can help make the boat easier to find. (Admittedly, had I gone for the more expensive RGB lights it would make that even easier in a place where other boats are also using underwater lights)

Final steps to untying the lines

At this point, there are just a few final tasks for us to complete before we can leave:

- Get our insurance riders for northern BC (north of the north tip of Vancouver Island and for the west coast of Vancouver Island)

- Get an EPIRB (Emergency Position-Indicating Radio Beacon) for the boat (emergency beacon that contacts satellites)

- Get PLBs (Personal Locator Beacon) for both of us (GPS + AIS beacons that are strapped to our lifejackets and are water-activated)

- Complete our set of sheets (horizontally-running lines that help control sails for you non-sailors) for the storm sails; at the moment I just have one of the four we need since I had been measuring things to ensure it was correct. Related: buy two more blocks (pulleys, for you non-sailors) for this same purpose

- Get a set of diesel and potable water jerrycans

- Assemble our ditch bag

We’ve also each got a number of miscellaneous personal tasks to finish such as downsizing/moving our storage units, ensuring we have enough of whatever medications we take for the next few months, etc. But we’re on-schedule, most of these remaining tasks are simply purchase tasks, and I’m feeling really good about where we’re at.

If you buy two more blocks, will you then be less likely to be three sheets to the wind?

Those knives are gorgeous. Fingers crossed you launch on time. So excited for you!