This past week we were able to complete the installation of our freezer; though perhaps a more correct description would be the conversion of the (unpowered) icebox to a freezer. The results are so far very good–as I write this the freezer temperature is sitting at -3.4°F.

If you’re interested to see some of the installation details, read on!

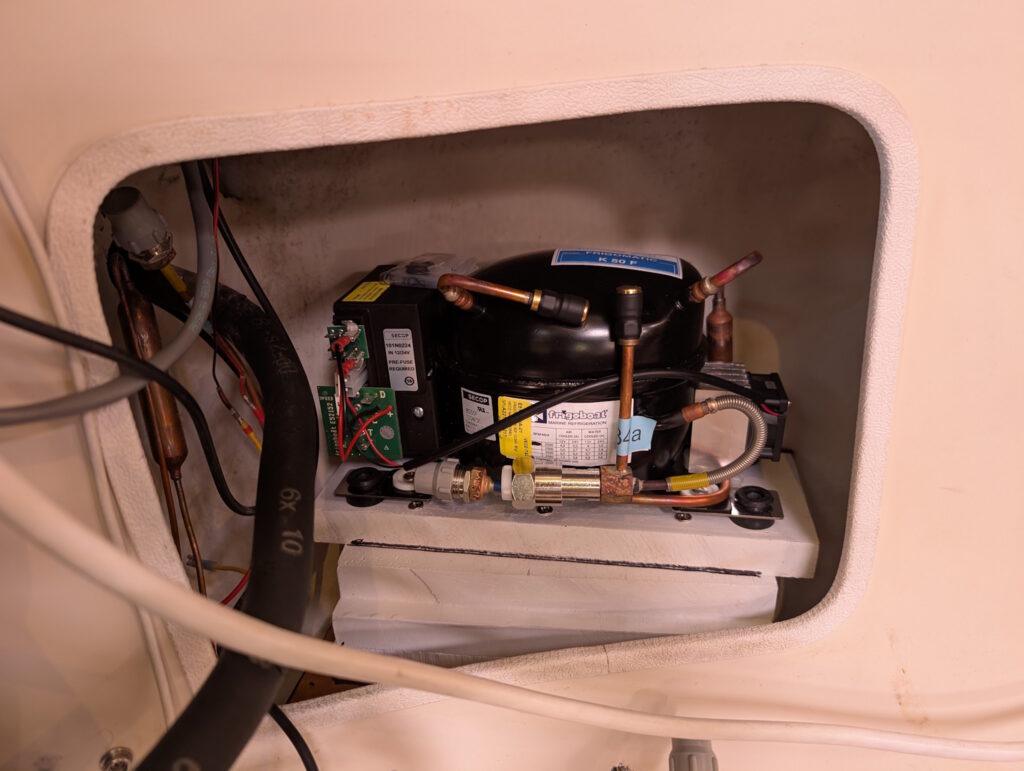

Installing a Frigoboat K50F on a Catalina 42

Per the heading, that’s what we’ve got: a keel-cooled Frigoboat K50F with a 200F cold plate. Installation wasn’t exactly what I’d call easy, but it was relatively straight-forward. You measure the box you’re putting the plate into, bend it carefully using a jig, heat gun, and 3″ ABS pipe, and then mount it inside using the offset mounts (to keep the plates from touching the walls, providing airflow on all sides. The most difficult part of the process was getting the 1.5″ diameter hole drilled between the insulated icebox and the compartment the compressor is in; we had that done professionally by CSR Marine while the boat was hauled out getting the keel cooler and a few other things installed/redone.

Then, nearby, you figure out how best to mount the compressor, and somewhere in a nearby area, under the waterline, you have the keel cooler installed. The three components then form a loop for the coolant to move through. I also then drilled a hole for and mounted a fan above the compressor to help keep air circulating since it’s in a fairly closed-up cubby hole behind our main settee.

In addition, before we filled the hole that the coolant lines and temperature sensor wires were routed through with expanding foam, I mounted a light on the underside of the door:

Once I’d filled the 1.5″ diameter hole with expanding foam, we were able to turn things on!

And, as you can see in this picture, it’s staying very nice and cold. I set the system to -5°F, and it’s been maintaining things between -4.9°F and -3°F, which is perfect.

We’ve got a working freezer!